How to Choose the Right Angle Grinder Hole Saw?

Angle grinder hole saws are versatile tools used for cutting precise circular holes in various materials such as metal, wood, plastic, and masonry. Selecting the right Angle Grinder Hole Saw is crucial to ensure efficient cutting, durability, and safety. For DIY enthusiasts, contractors, or industrial users, understanding the key factors that influence choice helps achieve better results and prevents tool damage or accidents.

Material Compatibility

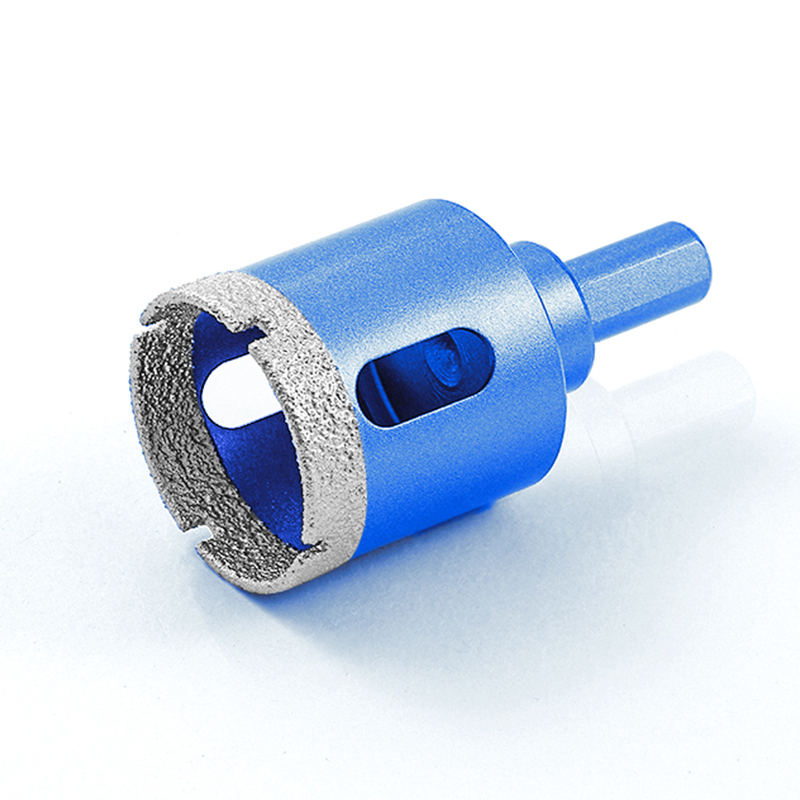

The first consideration when choosing an Angle Grinder Hole Saw is the material it will cut. Different hole saws are designed for specific materials. For example, carbide-tipped hole saws are suitable for metal and masonry, while bi-metal saws can handle wood and softer metals. Diamond-coated hole saws are ideal for hard materials like tiles or stone. Selecting a hole saw compatible with the material ensures clean cuts, reduces wear, and extends the tool's lifespan.

Hole Size and Depth

Another critical factor is the size of the hole to be cut. Hole saws come in various diameters, and it's important to select one that matches the project requirements. Depth is also a consideration; some hole saws are designed for shallow cuts, while others allow for deeper penetration. Choosing the correct size and depth ensures efficiency and prevents unnecessary strain on both the tool and the angle grinder.

Arbor and Attachment Type

Hole saws attach to angle grinders using arbors or adapters. Ensuring compatibility between the hole saw and the angle grinder is essential. Some hole saws require specific arbor sizes or designs, and using the wrong type can lead to poor performance or unsafe operation. Many manufacturers provide universal arbors, but checking specifications before purchase guarantees a secure fit and stable operation.

Durability and Build Quality

The durability of an Angle Grinder Hole Saw affects both performance and safety. High-quality materials, such as hardened steel, carbide tips, or diamond coatings, enhance cutting efficiency and reduce wear. Reinforced or well-constructed saws can withstand higher torque and prolonged use without deforming or chipping. Paying attention to build quality helps avoid frequent replacements and ensures consistent cutting results.

Speed and Compatibility with Grinder

Angle grinders operate at high RPMs, and the hole saw should be rated for the speed of the grinder. Using a hole saw not designed for high-speed operation can cause overheating, premature wear, or dangerous kickbacks. Checking manufacturer recommendations for maximum operating speed and ensuring the saw is compatible with the grinder's power and RPM rating is important for safety and efficiency.

Safety Considerations

Safety is an important aspect when choosing a hole saw. Features such as pilot drills, anti-kickback designs, and stable mounting systems contribute to safer operation. Wearing personal protective equipment, including gloves, eye protection, and hearing protection, is recommended. Selecting a hole saw with safety in mind reduces the risk of accidents and ensures a smoother cutting process.

Choosing the right Angle Grinder Hole Saw involves considering material compatibility, hole size and depth, arbor type, durability, speed rating, and safety features. Paying attention to these factors ensures efficient cutting, reduces wear on both the tool and the grinder, and maintains a safe working environment. Understanding the specifications and intended use of the hole saw allows users to select a tool that meets project requirements and provides reliable performance across various applications.