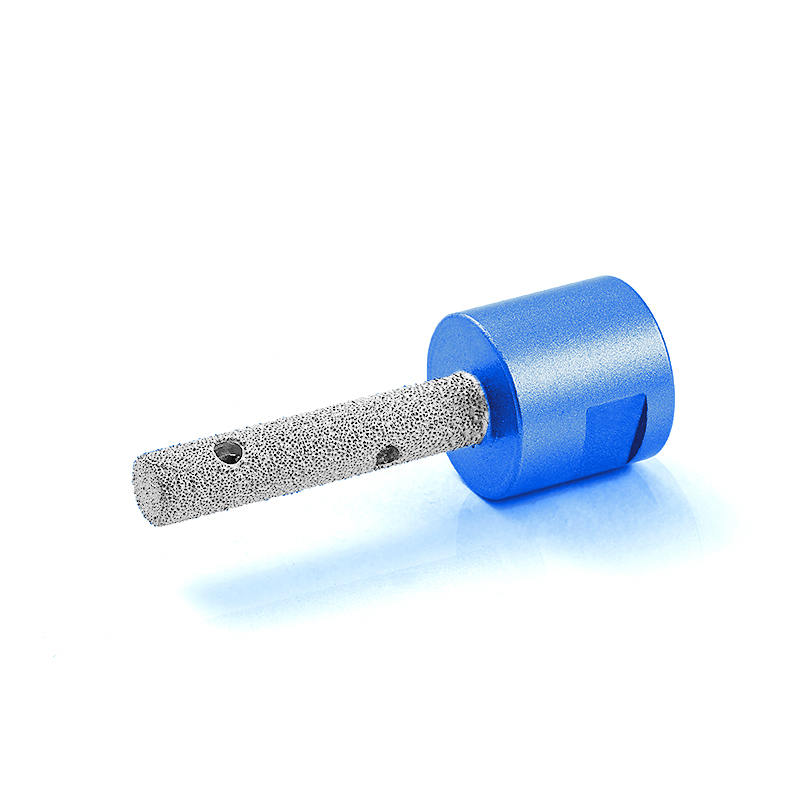

EG-A-002 Diamond Ceramic Hole Saw

Item No.: EG-A-002

Handle type: Round handle

Diamond grit size: 60/70#

Total length: 55mm

Specification: 3mm-160mm

Process: Plating

Product Introduction: This product is an upgraded version of EG-A-001, which increases the service life of the product and is suitable for drilling holes in materials such as glass, tiles, and marble.

About

-

Target

To create an honest enterprise for the responsibility To build a harmonious society.

-

Vision

Let every employee work happily To be a sustainable business excellence With the integrity of the enterprise image deeply.

-

Core Values

Run the business with integrity Give back to society with a loving heart.

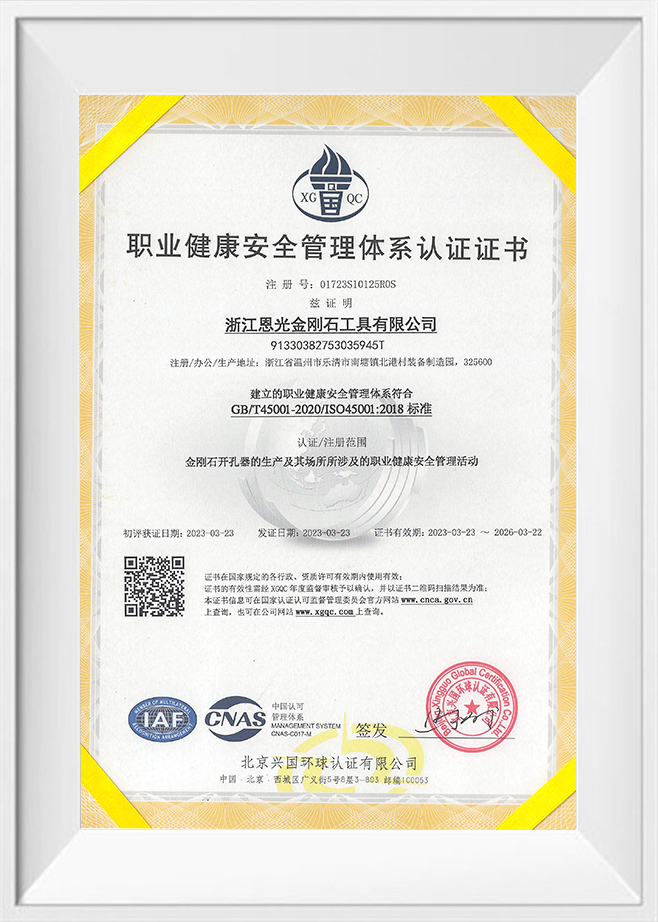

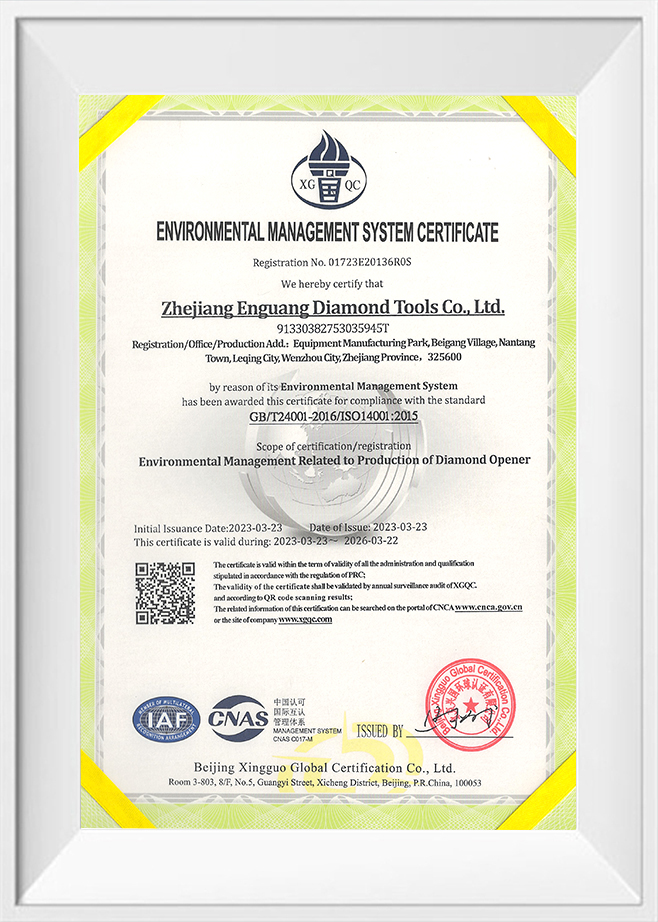

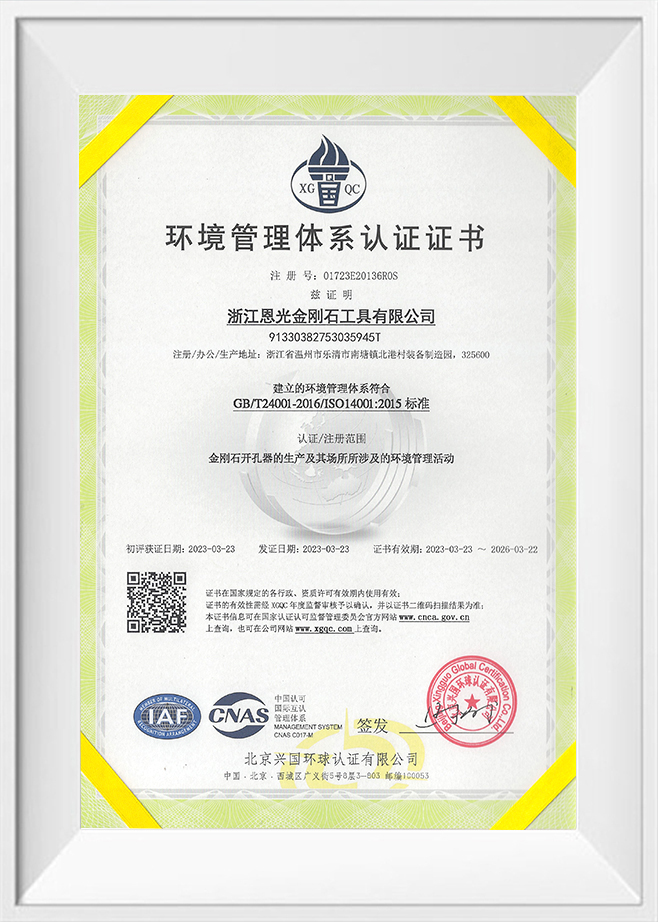

Zhejiang Enguang Diamond Tools Co., Ltd. was formally established in 2003, specializing in the production of diamond hole opener series products, which are suitable for opening holes in glass, ceramics, marble and other materials.

As a China high quality EG-A-002 Diamond Ceramic Hole Saw supplier and custom EG-A-002 Diamond Ceramic Hole Saw company, Enguang has a large number of CNC machine tools and green environmental protection electroplating workshops, which can provide customers with efficient and convenient ODM and OEM services to ensure long-term and stable production for customers!

-

Diamond core bits are essential tools for drilling concrete, stone, asphalt, and other hard material...

View More > 2026.02.24

2026.02.24

-

Drilling through hard materials such as ceramic tiles, granite, glass, or engineered stone requires ...

View More > 2026.02.20

2026.02.20

-

Tile installation, whether in residential or commercial projects, often requires precise cuts for pi...

View More > 2026.02.13

2026.02.13

-

In many construction and industrial applications, cutting through hard materials requires specialize...

View More > 2026.02.06

2026.02.06

-

Whether you are managing a construction project, running a manufacturing plant, or performing renov...

View More > 2026.01.27

2026.01.27

-

Whether you are a DIY enthusiast or a professional contractor, selecting the right cutting tool can...

View More > 2026.01.23

2026.01.23

-

A Polished Tile Hole Saw is designed specifically for cutting holes in polished tiles without causi...

View More > 2026.01.16

2026.01.16

-

A Vacuum Brazed Diamond Hole Saw is a specialized tool designed to cut through hard materials such ...

View More > 2026.01.09

2026.01.09

-

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability a...

View More > 2026.01.02

2026.01.02

-

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing...

View More > 2025.12.25

2025.12.25

-

Drilling through hard materials such as ceramics, glass, or stone can be challenging with conventio...

View More > 2025.12.19

2025.12.19

-

Working with polished tiles can be challenging due to their smooth surfaces and risk of cracking du...

View More > 2025.12.12

2025.12.12

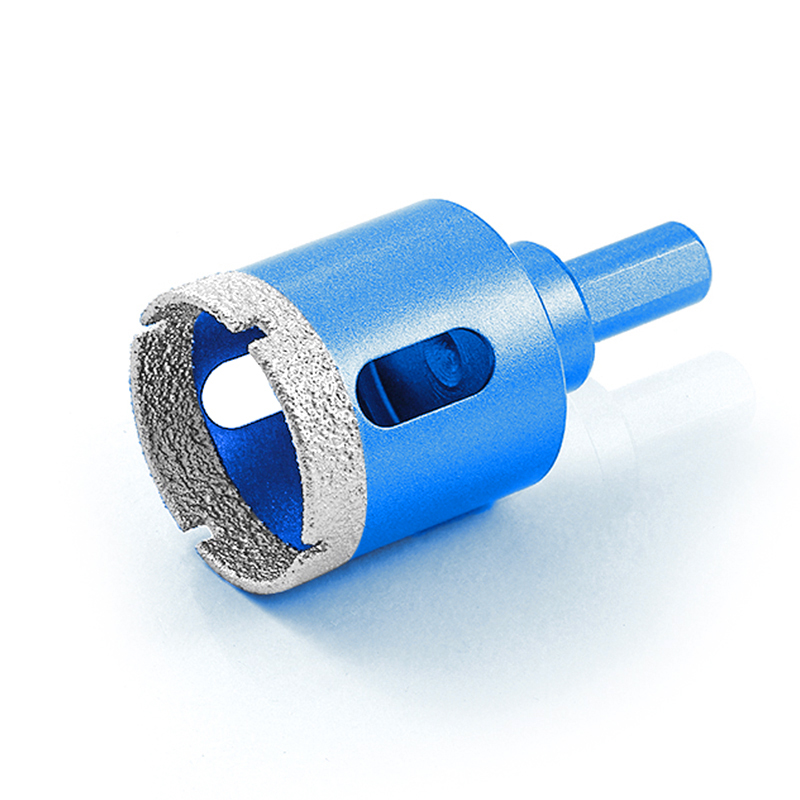

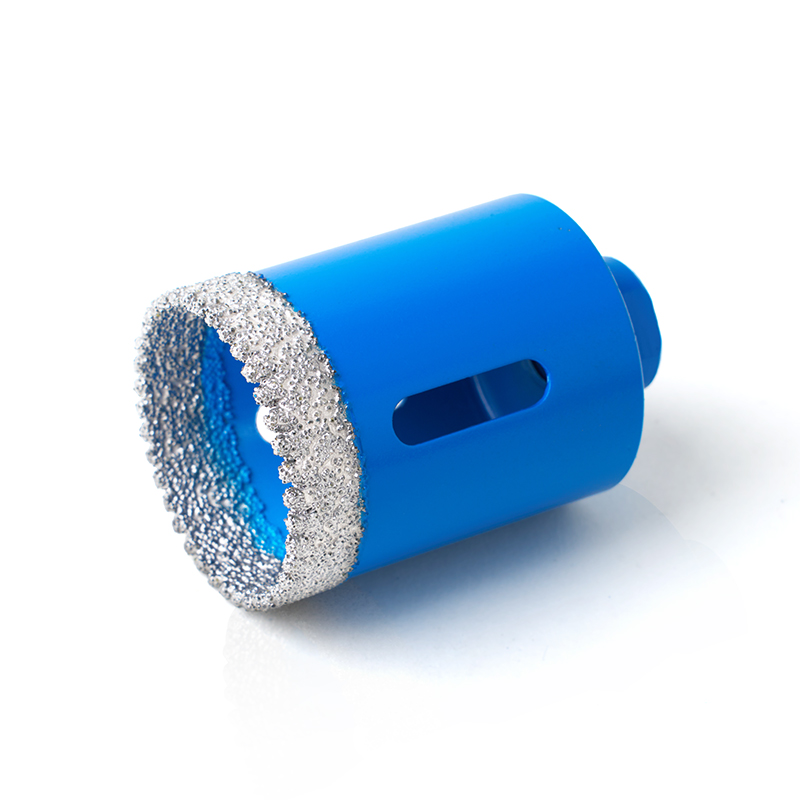

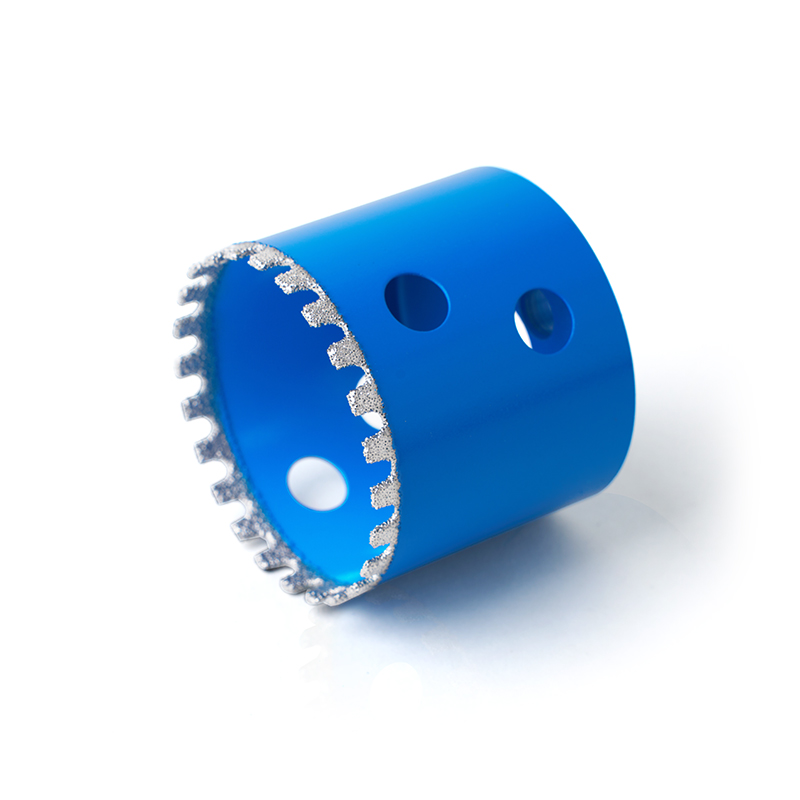

More Details About EG-A-002 Diamond Ceramic Hole Saw

The diamond ceramic hole saw is a high-performance tool designed for drilling holes in hard materials such as ceramics, polished tiles, marble, and granite. Compared with ordinary products, it has significantly improved service life, cutting efficiency, and versatility, and is favored by professional craftsmen and industry users.

The core part of the diamond ceramic hole saw is the high-hardness diamond blade embedded on its surface. Diamond is the hardest natural material known so far, so it is suitable for cutting extremely hard materials such as ceramics, polished tiles, marble, and granite. These diamond blades are not only hard, but also have outstanding wear resistance, and can remain sharp for a long time, ensuring stable cutting results and long service life.

Usually, diamond ceramic hole saws are designed with a multi-layer structure to ensure their stability and safety. In this design, the diamond blade layer is tightly embedded in the metal base, and the base provides the necessary support and stability to prevent vibration and deviation during high-speed rotation.

During the design process, manufacturers usually optimize the cooling system to ensure that the drill bit is effectively cooled during the cutting process. This not only improves cutting efficiency and working accuracy, but also prolongs the service life of the diamond blade and reduces the risk of blade damage and material deterioration due to overheating.

Due to the outstanding properties of diamond blades, diamond ceramic drills have a longer service life than traditional drill bits. Whether in personal home decoration or large-scale industrial production, this long life can significantly reduce the frequency of tool replacement, reduce the cost of use and maintenance costs.

The ultra-high hardness and sharp cutting edge of diamond enable diamond ceramic drills to quickly and accurately cut materials such as ceramics, polished tiles, marble and granite. This efficient cutting ability not only improves work efficiency, but also ensures the quality and accuracy of the holes, meeting professional standards and technical requirements.

Diamond ceramic drills are not limited to ceramic materials, but can also be used for opening holes in a variety of hard materials such as polished tiles, marble, granite, etc. This versatility makes it one of the indispensable tools in the construction industry, decoration industry and industrial manufacturing.

In the field of architectural decoration, diamond ceramic drills are widely used to open holes in wall tiles, floor tiles, bathroom tiles, kitchen countertop tiles, etc., and can provide accurate and efficient hole opening solutions for various decoration projects.

In industrial manufacturing, diamond ceramic drills are often used to process workpieces made of hard materials such as marble and granite, and are used to manufacture furniture, industrial equipment, and building materials, etc., to provide precise and high-quality hole processing for the production process.

Diamond ceramic drills have an important influence in the market due to their outstanding performance and wide range of applications. Manufacturers continue to optimize and innovate product designs to meet users' needs for high-quality and efficient tools, thus winning the favor and trust of the market. With the development of the construction and decoration industry and the increasing requirements for material processing accuracy, diamond ceramic drills are expected to continue to expand their market share and influence in the future.

Whether it is professional construction workers or individual DIY enthusiasts, diamond ceramic drills can provide reliable solutions to help achieve various hole opening needs and promote the development and progress of the construction and decoration industry.