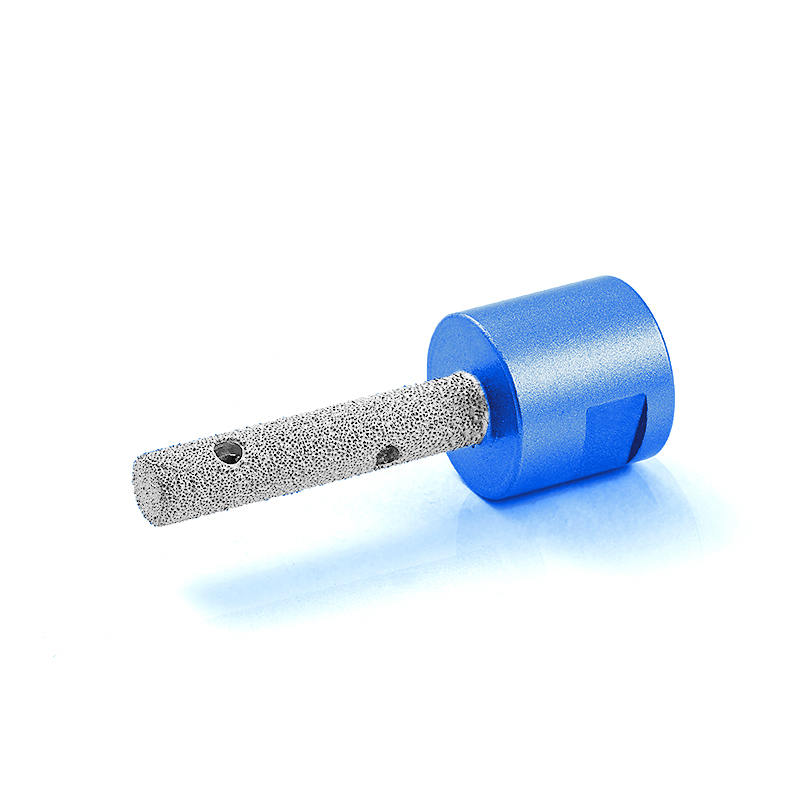

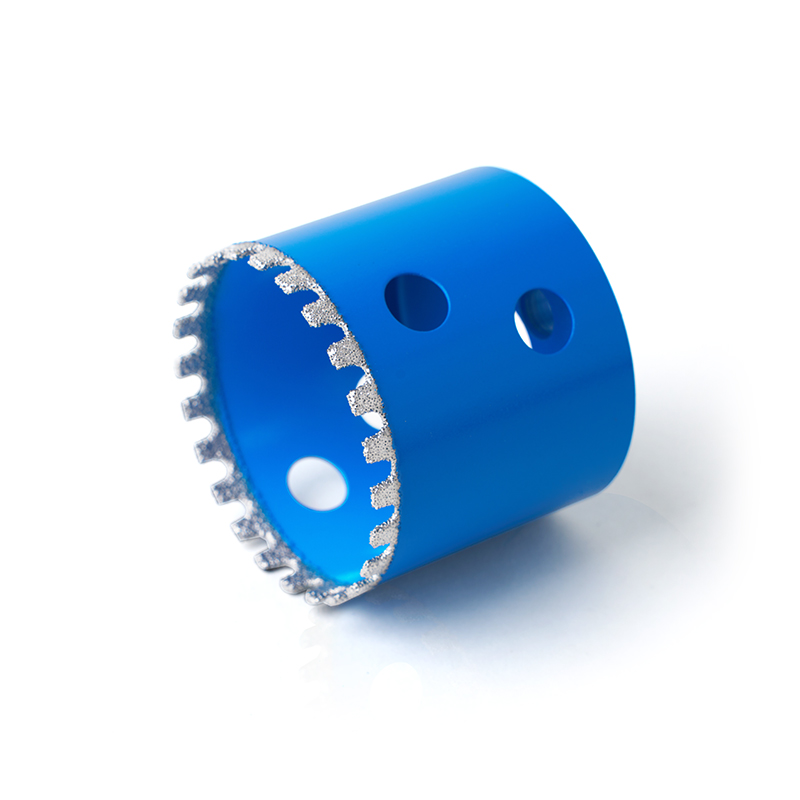

EG-A-010 Diamond Marble Hole Saw With Center Drill

Item No.: EG-A-010

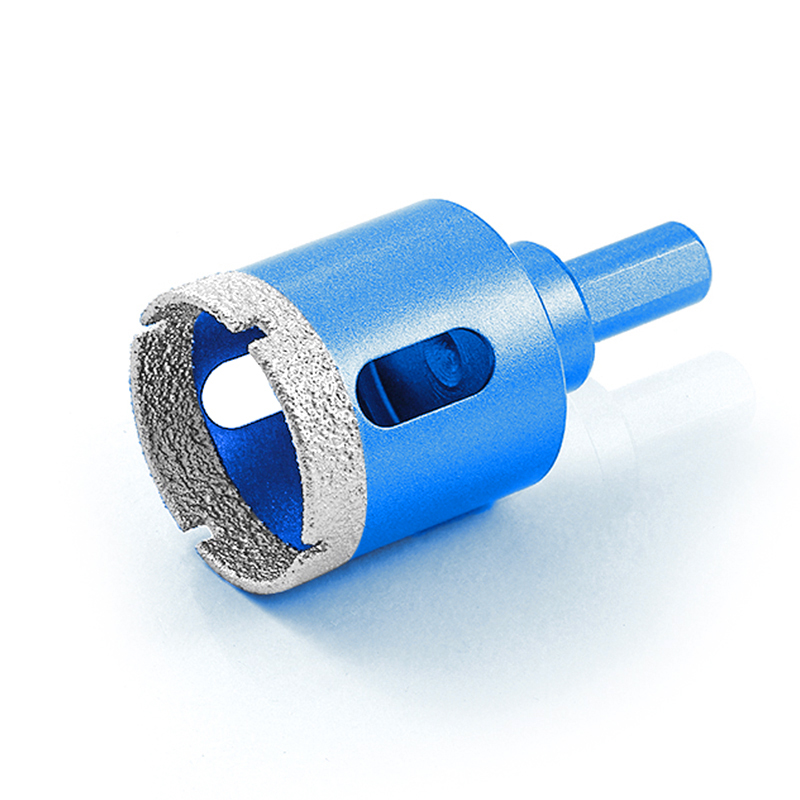

Handle type: Triangle handle

Diamond grit size: 46#

Specification: 16mm-120mm

Process: Plating

Product Introduction: This product has added a positioning drill to enable more accurate positioning, and is suitable for relatively hard materials such as glass, tiles, marble, and granite.

About

-

Target

To create an honest enterprise for the responsibility To build a harmonious society.

-

Vision

Let every employee work happily To be a sustainable business excellence With the integrity of the enterprise image deeply.

-

Core Values

Run the business with integrity Give back to society with a loving heart.

Zhejiang Enguang Diamond Tools Co., Ltd. was formally established in 2003, specializing in the production of diamond hole opener series products, which are suitable for opening holes in glass, ceramics, marble and other materials.

As a China high quality EG-A-010 Diamond Marble Hole Saw With Center Drill supplier and custom EG-A-010 Diamond Marble Hole Saw With Center Drill company, Enguang has a large number of CNC machine tools and green environmental protection electroplating workshops, which can provide customers with efficient and convenient ODM and OEM services to ensure long-term and stable production for customers!

-

Diamond core bits are essential tools for drilling concrete, stone, asphalt, and other hard material...

View More > 2026.02.24

2026.02.24

-

Drilling through hard materials such as ceramic tiles, granite, glass, or engineered stone requires ...

View More > 2026.02.20

2026.02.20

-

Tile installation, whether in residential or commercial projects, often requires precise cuts for pi...

View More > 2026.02.13

2026.02.13

-

In many construction and industrial applications, cutting through hard materials requires specialize...

View More > 2026.02.06

2026.02.06

-

Whether you are managing a construction project, running a manufacturing plant, or performing renov...

View More > 2026.01.27

2026.01.27

-

Whether you are a DIY enthusiast or a professional contractor, selecting the right cutting tool can...

View More > 2026.01.23

2026.01.23

-

A Polished Tile Hole Saw is designed specifically for cutting holes in polished tiles without causi...

View More > 2026.01.16

2026.01.16

-

A Vacuum Brazed Diamond Hole Saw is a specialized tool designed to cut through hard materials such ...

View More > 2026.01.09

2026.01.09

-

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability a...

View More > 2026.01.02

2026.01.02

-

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing...

View More > 2025.12.25

2025.12.25

-

Drilling through hard materials such as ceramics, glass, or stone can be challenging with conventio...

View More > 2025.12.19

2025.12.19

-

Working with polished tiles can be challenging due to their smooth surfaces and risk of cracking du...

View More > 2025.12.12

2025.12.12

More Details About EG-A-010 Diamond Marble Hole Saw With Center Drill

The diamond marble hole saw with the center drill is a drilling tool designed for hard materials. It achieves precise positioning by adding a center drill, thereby improving the accuracy and efficiency of drilling.

Design features

1. Center drill positioning: The design of the center drill enables this hole saw to quickly and accurately locate the drilling position when working on hard materials, reducing errors.

2. Removable center drill: The center drill can be taken out after use so that the rotation and cutting efficiency of the hole saw will not be affected during the drilling process.

Size range

The size range of the diamond marble hole saw with the center drill is from 16mm to 120mm, which provides a wide range of choices for drilling needs of different sizes. Whether it is home decoration, industrial manufacturing, or professional stone processing, you can find the right size.

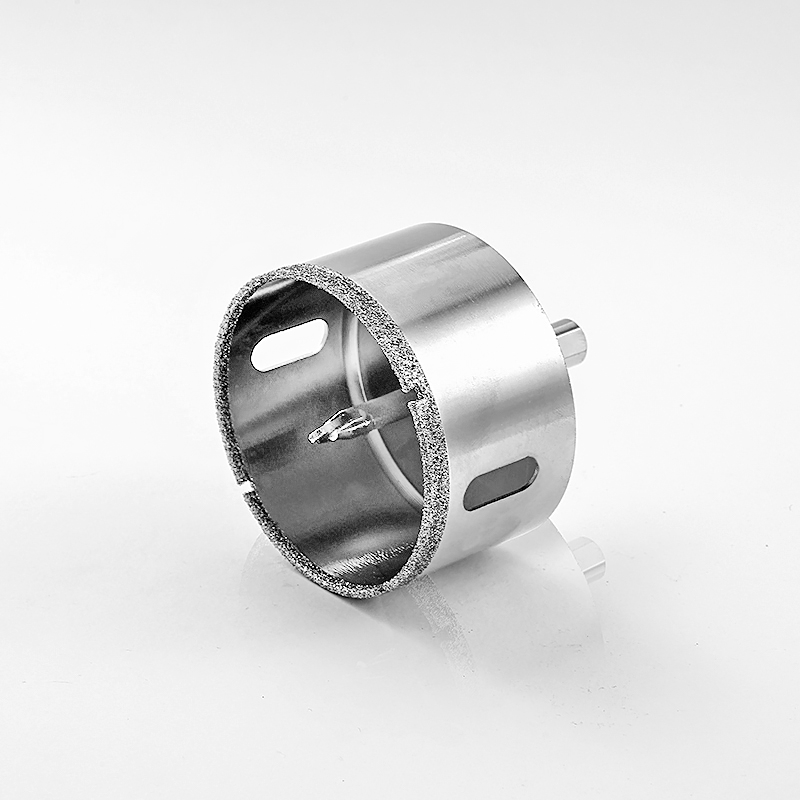

Material and structure

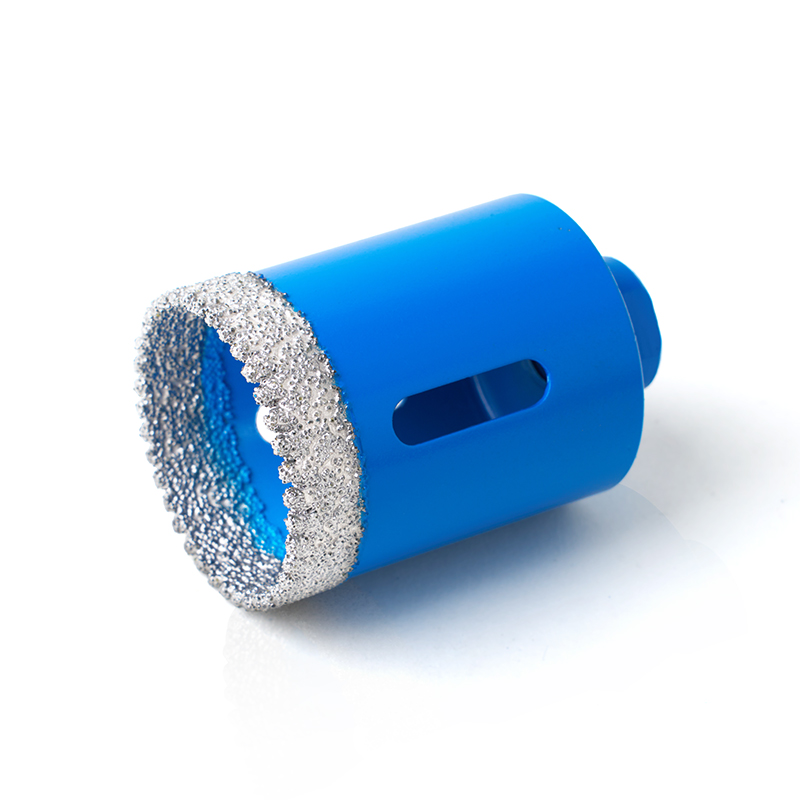

1. Diamond cutter head: The cutter head part of the hole saw is made of high-density diamond particles, which are evenly distributed on the surface of the cutter head, ensuring stability and durability during the drilling process.

2. Precision manufacturing: The manufacturing process of the hole saw adopts precision technology to ensure the accuracy and concentricity of the cutter head, thereby improving the accuracy and efficiency of drilling.

Application areas

1. Construction industry: In construction, this hole saw can be used to drill holes for installing pipes, wires, ventilation systems, etc.

2. Decoration industry: In interior decoration, it can be used to drill holes for installing lamps, switches, sockets, etc.

3. Stone processing: In the stone processing industry, this hole saw is an ideal choice for cutting and drilling hard stones such as marble and granite.

Operation steps

1. Positioning: use the center drill to locate the drilling position on the hard material.

2. Fixing: Fix the hole saw on the electric drill to ensure that it is aligned with the position where the center drill is located.

3. Drilling: Start the electric drill, slowly push the hole saw, and start drilling.

4. Remove the center drill: After drilling starts, remove the center drill and continue drilling to the desired depth.

Precautions for use

- Coolant: During the drilling process, it is recommended to use coolant to extend the service life of the drill and prevent overheating.

- Speed control: When drilling, the speed of the electric drill should be controlled to avoid excessive wear or breakage of the cutter head.

- Regular inspection: The wear of the drill should be checked regularly during use and replaced if necessary.

Maintenance and care

- Cleaning: After drilling, the drill should be cleaned in time to remove residual debris and dust.

- Storage: When not in use, the drill should be stored in a dry and clean environment to avoid moisture and corrosion.

Through the above descriptions, we can see that the diamond marble drill with center drill is an efficient, accurate, and durable drilling tool, which has a wide range of application prospects in the drilling of hard materials.