EG-A-001B Diamond Glass Hole Saw With Center Drill

Item No.: EG-A-001B

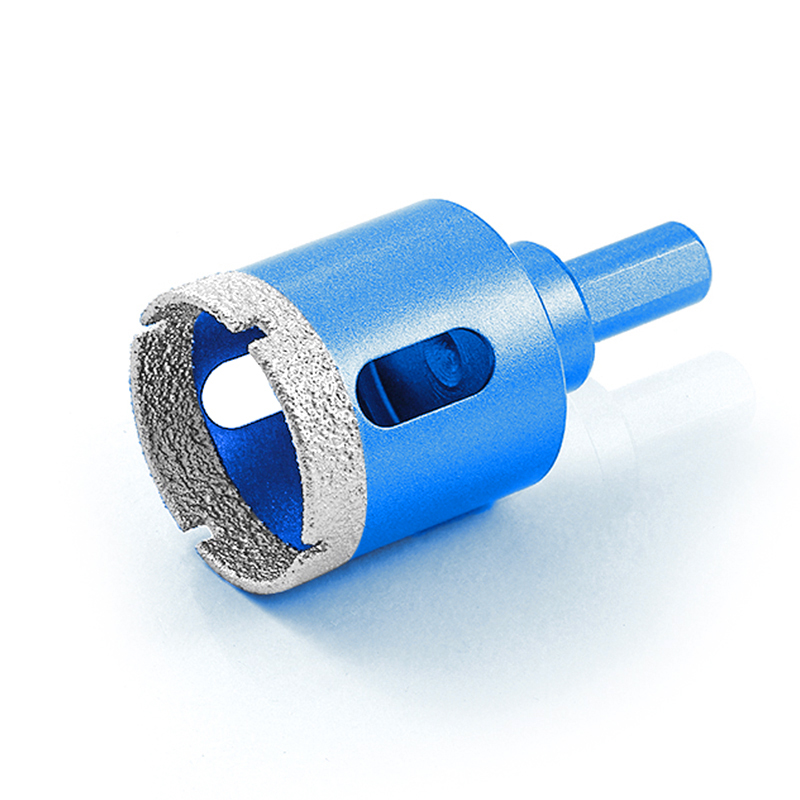

Handle type: Round handle

Diamond grit size: 70/80#

Total length: 55mm

Specification: 20mm-120mm

Process: Plating

Product Introduction: This product is suitable for materials such as glass and tiles. The addition of a positioning drill allows novices to position more accurately, and then take out the positioning drill to easily complete the hole opening operation.

About

-

Target

To create an honest enterprise for the responsibility To build a harmonious society.

-

Vision

Let every employee work happily To be a sustainable business excellence With the integrity of the enterprise image deeply.

-

Core Values

Run the business with integrity Give back to society with a loving heart.

Zhejiang Enguang Diamond Tools Co., Ltd. was formally established in 2003, specializing in the production of diamond hole opener series products, which are suitable for opening holes in glass, ceramics, marble and other materials.

As a China high quality EG-A-001B Diamond Glass Hole Saw With Center Drill supplier and custom EG-A-001B Diamond Glass Hole Saw With Center Drill company, Enguang has a large number of CNC machine tools and green environmental protection electroplating workshops, which can provide customers with efficient and convenient ODM and OEM services to ensure long-term and stable production for customers!

-

Diamond core bits are essential tools for drilling concrete, stone, asphalt, and other hard material...

View More > 2026.02.24

2026.02.24

-

Drilling through hard materials such as ceramic tiles, granite, glass, or engineered stone requires ...

View More > 2026.02.20

2026.02.20

-

Tile installation, whether in residential or commercial projects, often requires precise cuts for pi...

View More > 2026.02.13

2026.02.13

-

In many construction and industrial applications, cutting through hard materials requires specialize...

View More > 2026.02.06

2026.02.06

-

Whether you are managing a construction project, running a manufacturing plant, or performing renov...

View More > 2026.01.27

2026.01.27

-

Whether you are a DIY enthusiast or a professional contractor, selecting the right cutting tool can...

View More > 2026.01.23

2026.01.23

-

A Polished Tile Hole Saw is designed specifically for cutting holes in polished tiles without causi...

View More > 2026.01.16

2026.01.16

-

A Vacuum Brazed Diamond Hole Saw is a specialized tool designed to cut through hard materials such ...

View More > 2026.01.09

2026.01.09

-

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability a...

View More > 2026.01.02

2026.01.02

-

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing...

View More > 2025.12.25

2025.12.25

-

Drilling through hard materials such as ceramics, glass, or stone can be challenging with conventio...

View More > 2025.12.19

2025.12.19

-

Working with polished tiles can be challenging due to their smooth surfaces and risk of cracking du...

View More > 2025.12.12

2025.12.12

More Details About EG-A-001B Diamond Glass Hole Saw With Center Drill

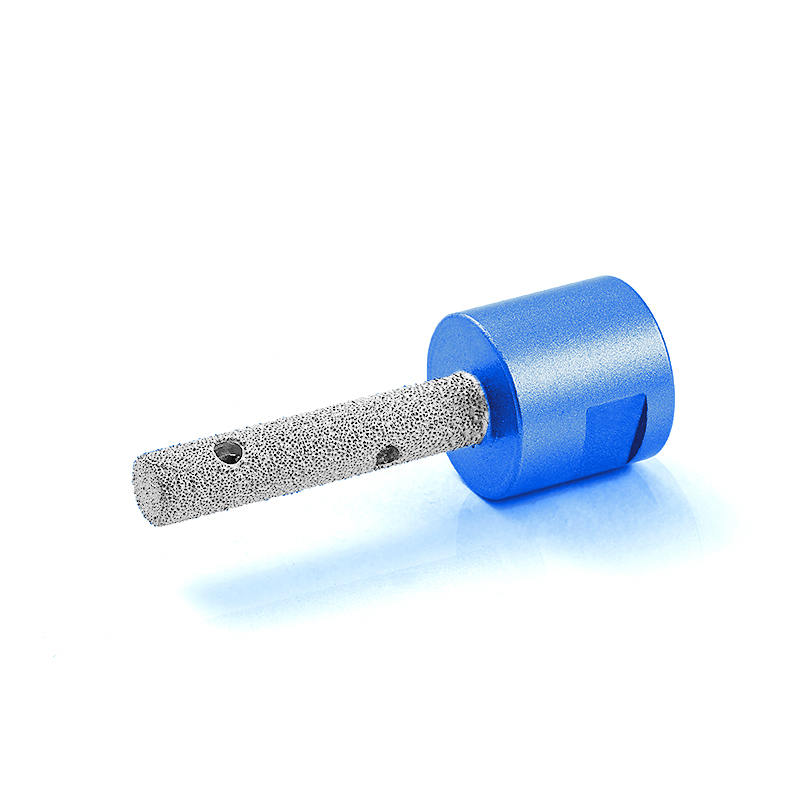

The diamond glass hole saw with center drill is a specially designed tool designed for drilling glass and similar materials. Unlike ordinary diamond glass hole saws, it has the function of a center drill, which brings many advantages and conveniences in actual operation.

1. Product Features

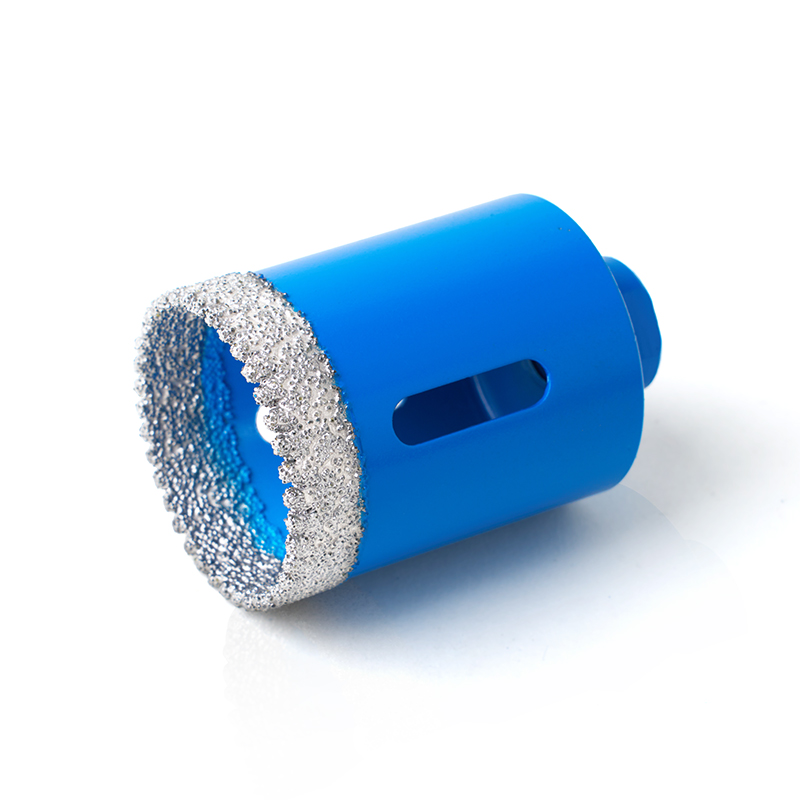

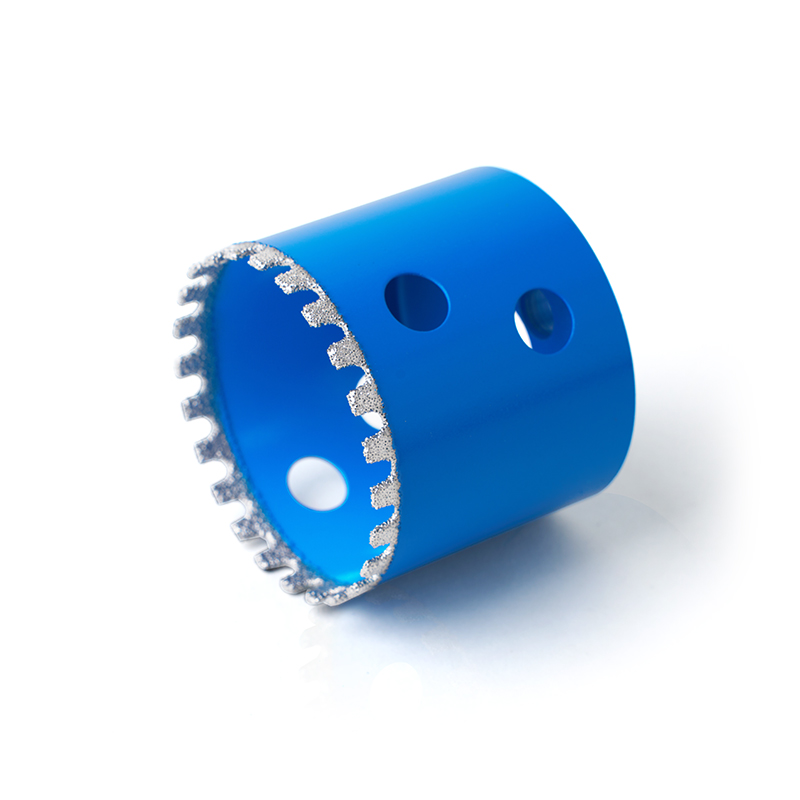

Diamond Blade Layer

The core part of the diamond glass hole saw with center drill is its drill head covered with a diamond blade layer. These diamond blades have extremely high hardness and wear resistance, and can effectively cut hard materials such as glass, tiles, quartz, etc. without causing blade failure or damage.

Center Drill Design

Unlike ordinary hole saws, the diamond glass hole saw with center drill is equipped with a center drill at the center of the drill head. The role of this center drill is very important. It can pre-drill holes in the initial stage to provide accurate guidance and positioning for the diamond blade. In this way, during the actual cutting process, the position of the hole can be ensured to be accurate, avoiding the risk of drill bit deviation or material damage.

Stable Structure

The design structure of the diamond glass hole saw with center drill is very stable, usually supported by a metal base to support the diamond blade layer and center drill. This structure not only enhances the stability of the drill bit, but also improves its durability and safety. In addition, the surface of the drill bit is usually designed with cooling holes for heat dissipation and debris discharge, ensuring that the cutting effect will not be affected by overheating during high-intensity use.

2. Application scenarios

Architectural decoration

Diamond glass hole saw with center drill is widely used in the field of architectural decoration, such as opening glass doors and windows, glass mirrors, etc. The precise positioning of the center drill and the efficient cutting ability of the diamond blade make it an indispensable tool for installing building structures with glass materials.

Crafts production

In the field of crafts production, especially in occasions where fine processing is required on glass, diamond glass hole saw with center drill can provide high-precision and high-quality holes to meet various complex design requirements.

Home decoration

Common applications in home decoration include the installation of bathroom shower room glass doors, the opening of kitchen glass countertops, etc. The existence of the center drill can help users easily locate and operate, ensuring a safe and efficient opening process.

Industrial Manufacturing

In industrial manufacturing, diamond glass drill with center drill is often used for processing glass panels or transparent materials of mechanical equipment. Its efficient cutting ability and precise positioning characteristics can improve production efficiency and product quality.

3. How to use

The steps of using diamond glass drill with center drill are relatively simple, mainly including the following steps:

- Preparation: Make sure the surface of the drill bit and the working material are clean, and take safety precautions.

- Positioning: Use the center drill to drill holes at the predetermined position to ensure an accurate starting point.

- Cutting: Place the diamond blade part at the pre-drilled hole, and gradually increase the cutting pressure and speed until the entire hole opening process is completed.

- Cooling: Maintain proper cooling during the cutting process to avoid overheating and damage to the drill bit and material.

Diamond glass drill with center drill has become an ideal choice for professional and daily applications through its unique design and efficient performance. It can not only meet the needs of high-precision and high-quality drilling of glass and similar materials, but also significantly improve work efficiency and operational safety.