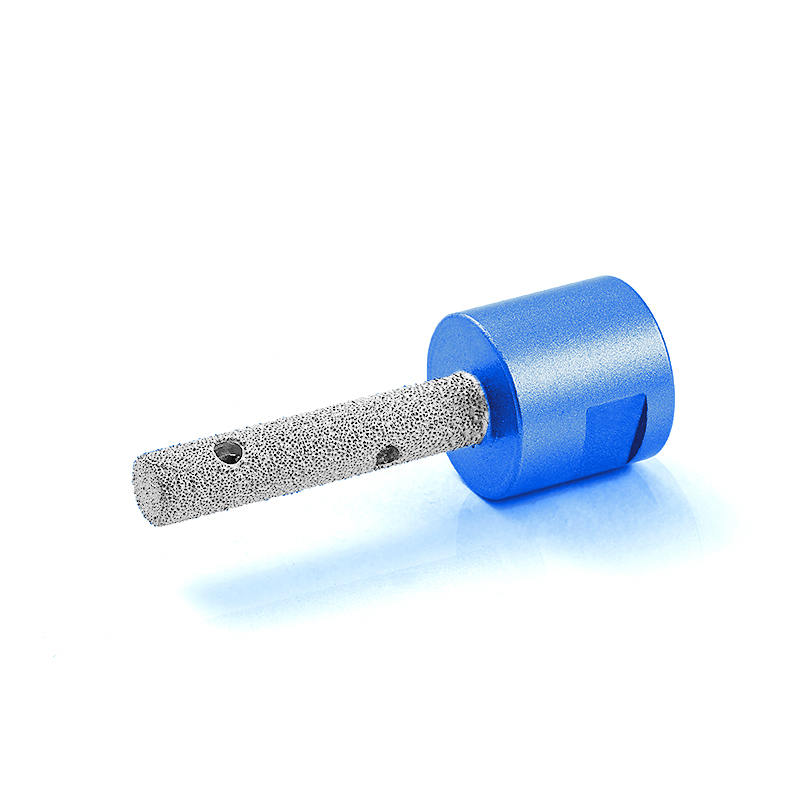

EG-A-009 Angle Grinder-Specific Electroplated Diamond Hole Saw

Item No.: EG-A-009

Handle type: M14, M10, 5/8-11

Diamond grit size: 46#

Specification: 6mm-120mm

Process: Plating

Product Introduction: This product is installed on an angle grinder and is suitable for drilling holes in materials such as glass, tiles, marble, and granite.

About

-

Target

To create an honest enterprise for the responsibility To build a harmonious society.

-

Vision

Let every employee work happily To be a sustainable business excellence With the integrity of the enterprise image deeply.

-

Core Values

Run the business with integrity Give back to society with a loving heart.

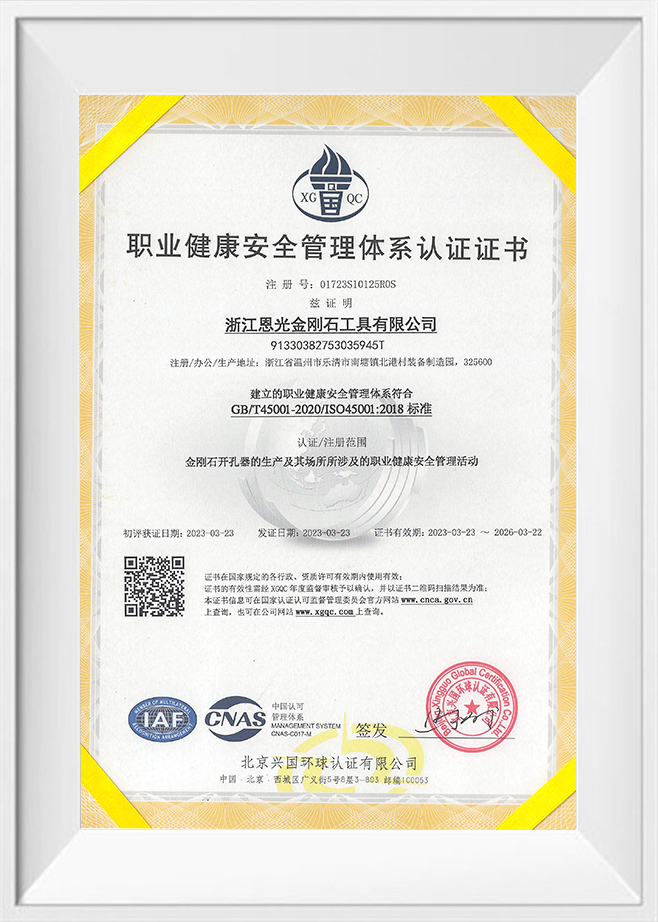

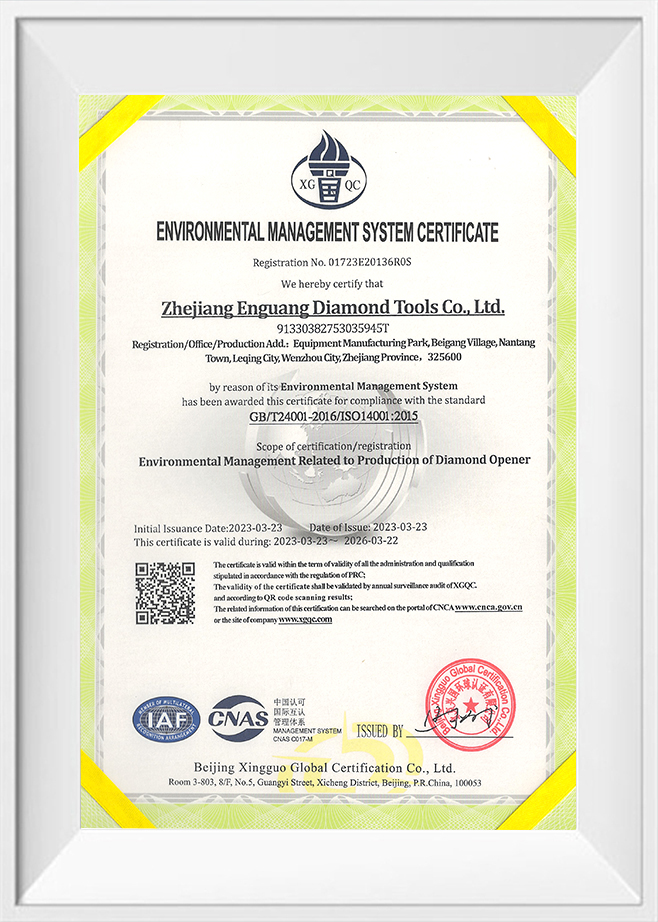

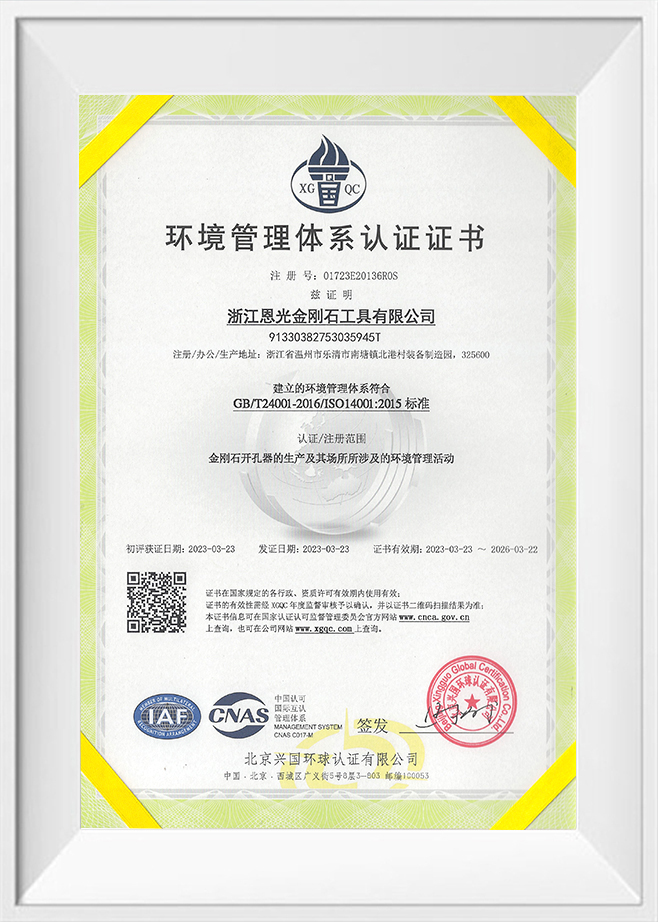

Zhejiang Enguang Diamond Tools Co., Ltd. was formally established in 2003, specializing in the production of diamond hole opener series products, which are suitable for opening holes in glass, ceramics, marble and other materials.

As a China high quality EG-A-009 Angle Grinder-Specific Electroplated Diamond Hole Saw supplier and custom EG-A-009 Angle Grinder-Specific Electroplated Diamond Hole Saw company, Enguang has a large number of CNC machine tools and green environmental protection electroplating workshops, which can provide customers with efficient and convenient ODM and OEM services to ensure long-term and stable production for customers!

-

Diamond core bits are essential tools for drilling concrete, stone, asphalt, and other hard material...

View More > 2026.02.24

2026.02.24

-

Drilling through hard materials such as ceramic tiles, granite, glass, or engineered stone requires ...

View More > 2026.02.20

2026.02.20

-

Tile installation, whether in residential or commercial projects, often requires precise cuts for pi...

View More > 2026.02.13

2026.02.13

-

In many construction and industrial applications, cutting through hard materials requires specialize...

View More > 2026.02.06

2026.02.06

-

Whether you are managing a construction project, running a manufacturing plant, or performing renov...

View More > 2026.01.27

2026.01.27

-

Whether you are a DIY enthusiast or a professional contractor, selecting the right cutting tool can...

View More > 2026.01.23

2026.01.23

-

A Polished Tile Hole Saw is designed specifically for cutting holes in polished tiles without causi...

View More > 2026.01.16

2026.01.16

-

A Vacuum Brazed Diamond Hole Saw is a specialized tool designed to cut through hard materials such ...

View More > 2026.01.09

2026.01.09

-

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability a...

View More > 2026.01.02

2026.01.02

-

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing...

View More > 2025.12.25

2025.12.25

-

Drilling through hard materials such as ceramics, glass, or stone can be challenging with conventio...

View More > 2025.12.19

2025.12.19

-

Working with polished tiles can be challenging due to their smooth surfaces and risk of cracking du...

View More > 2025.12.12

2025.12.12

More Details About EG-A-009 Angle Grinder-Specific Electroplated Diamond Hole Saw

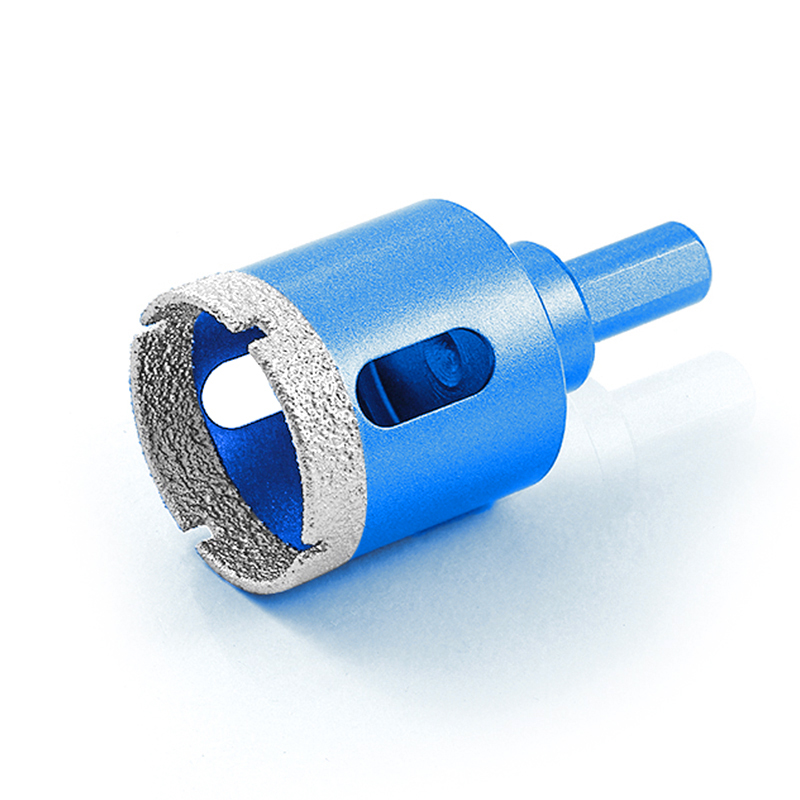

The Angle Grinder-Specific Electroplated Diamond Hole Saw is a specialized tool designed for drilling precise holes in hard materials using an angle grinder. This product features an electroplated diamond coating, coupled with an M14 thread that allows it to be easily mounted on standard angle grinders.

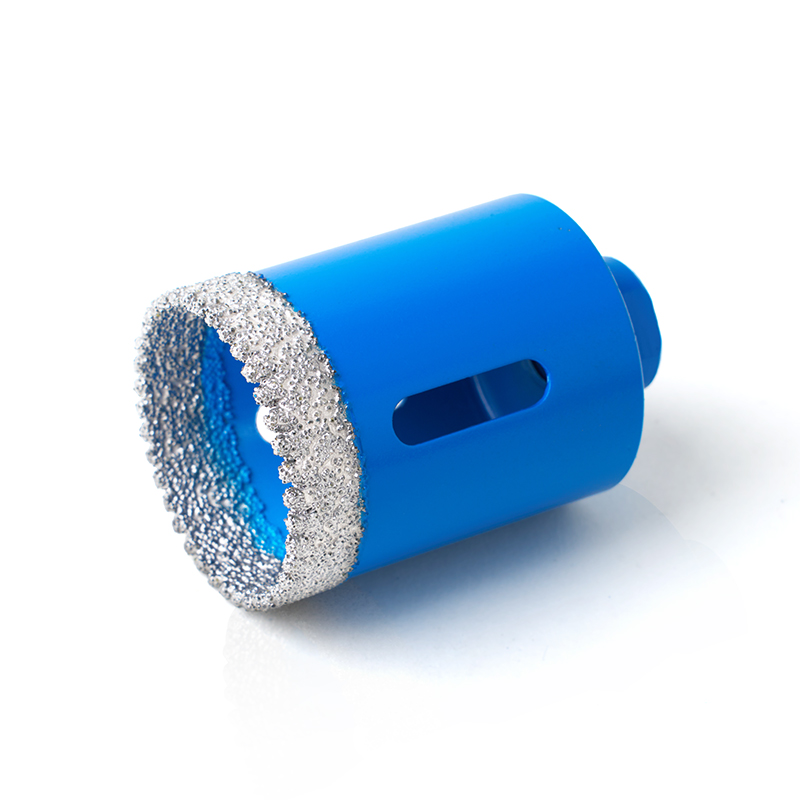

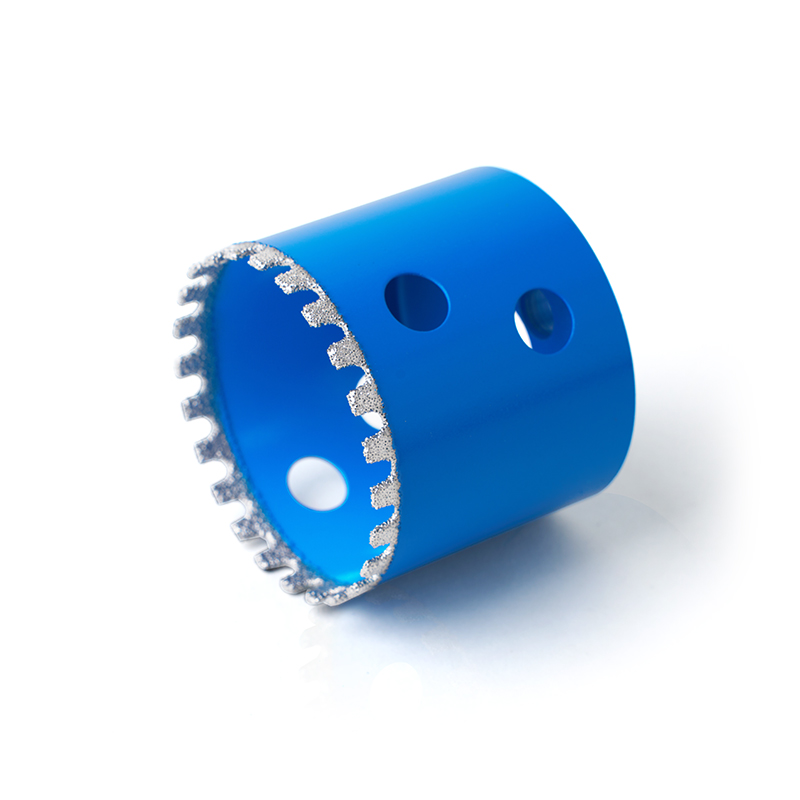

The core technology of the Angle Grinder-Specific Electroplated Diamond Hole Saw lies in its electroplated diamond coating. This coating consists of diamond particles that are embedded and securely bonded onto the hole saw's surface using an electroplating process. Electroplating ensures a uniform distribution of diamonds across the cutting edge, providing sharpness and durability.

The hole saw is equipped with an M14 threaded connection, which is compatible with standard angle grinders available in the market. This threaded connection ensures secure attachment and stable operation during drilling, minimizing vibrations and enhancing safety.

Due to the diamond coating, the hole saw offers high precision drilling capabilities in hard materials such as porcelain, ceramic tiles, granite, marble, and glass. It allows for clean and accurate hole cutting without causing cracks or damage to the surrounding material, making it suitable for both professional and DIY applications.

Many models of electroplated diamond hole saws feature strategically placed cooling holes. These holes help dissipate heat generated during drilling, preventing overheating of the tool and the material being drilled. This feature extends the tool's lifespan and ensures consistent performance over prolonged periods of use.

The Angle Grinder-Specific Electroplated Diamond Hole Saw is versatile and suitable for a wide range of applications. It is commonly used in construction and renovation projects for installing pipes, faucets, and electrical conduits. It is also ideal for creating holes in countertops, tiles, and other hard surfaces.

The diamond coating provides exceptional durability and longevity compared to traditional hole saws. Diamonds are extremely hard and wear-resistant, ensuring that the hole saw maintains its cutting performance over many uses. This durability reduces the need for frequent replacements, thereby lowering overall maintenance costs.

Mounting the hole saw onto an angle grinder is straightforward due to its M14 threaded connection. This makes it accessible for both professionals and DIY enthusiasts who prefer the versatility and power of angle grinders for various cutting tasks.

Despite its advanced technology and durability, the electroplated diamond hole saw remains cost-effective in the long run. Its ability to perform multiple drilling tasks without significant wear ensures a high return on investment for users in terms of reduced downtime and increased productivity.

In the construction industry, this hole saw is essential for tasks such as installing plumbing fixtures and electrical components. It is used for creating precise holes in materials like tiles, stones, and facilitating efficient and accurate installations.

Manufacturers rely on electroplated diamond hole saws for precise machining operations in the production of furniture, ceramics, and other fabricated materials. The tool's ability to maintain cutting accuracy and performance under demanding industrial conditions enhances operational efficiency.

The Angle Grinder-Specific Electroplated Diamond Hole Saw represents a pivotal advancement in drilling technology, offering exceptional cutting performance and durability with its electroplated diamond coating. Its compatibility with angle grinders makes it a versatile tool for professionals and DIYers alike, capable of handling demanding drilling tasks in hard materials.