How Do Diamond Core Bit Manufacturers Adapt to Different Drilling Needs?

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing precise drilling through hard materials such as concrete, stone, and asphalt. Behind these tools are diamond core bit manufacturers, which focus on producing durable and high-performance bits. Understanding their manufacturing processes helps reveal how these manufacturers maintain quality, precision, and efficiency.

1. Material Selection and Preparation

A diamond core bit manufacturer begins by selecting high-quality materials. Industrial diamonds are chosen based on hardness, size, and toughness to withstand wear during drilling. Steel or alloy cores are prepared for bonding the diamonds securely. The metal core may undergo heat treatment, cleaning, or surface preparation to ensure strong adhesion of the diamond segments. Material selection is critical for maintaining cutting performance and prolonging the tool's lifespan.

2. Segment Fabrication and Bonding

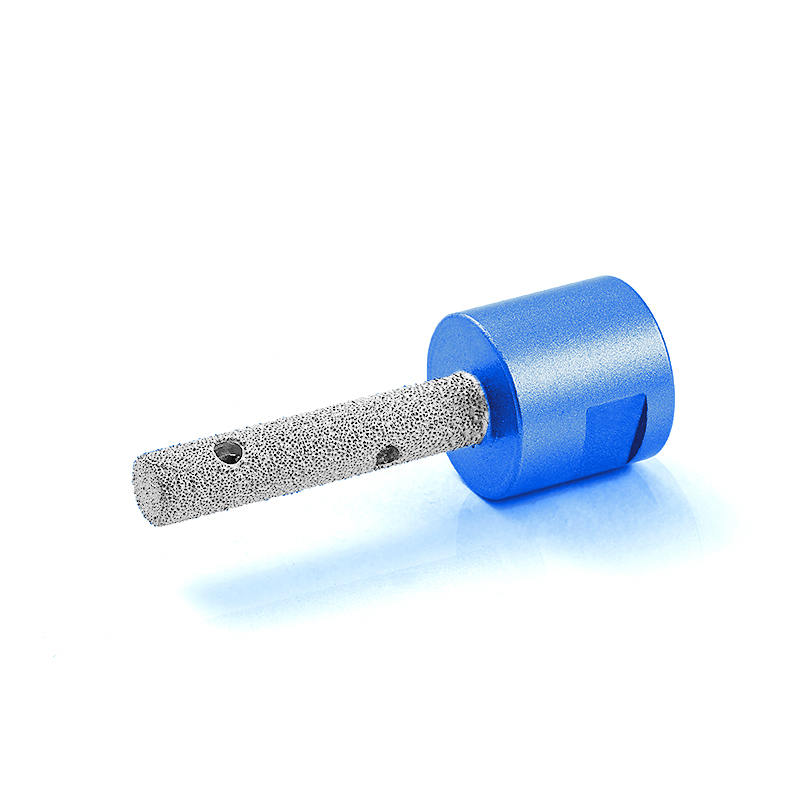

The next stage in a diamond core bit manufacturer is creating the cutting segments. Diamonds are mixed with a metallic bond, then pressed into shape and attached to the core. Manufacturers may use brazing, laser welding, or sintering methods depending on the design and application. The bonding technique ensures the diamond segments remain secure under high stress and temperatures during drilling. Uniform distribution of diamond particles is also crucial for smooth and efficient cutting.

3. Precision Manufacturing and Balancing

Precision is key in a diamond core bit manufacturer. The core bit must be perfectly round and balanced to prevent wobbling or vibration during use. CNC machines and advanced measuring tools are often employed to achieve tight tolerances. Proper balancing reduces wear, enhances drilling accuracy, and extends the life of both the bit and the drilling equipment. Many manufacturers also provide various sizes and configurations to match different drilling machines and materials.

4. Testing and Quality Control

A diamond core bit manufacturer employs rigorous testing to ensure performance. Bits are tested for cutting speed, wear resistance, segment retention, and heat tolerance. Visual inspections check for cracks, uneven bonding, or surface defects. Some manufacturers conduct real-world trials simulating concrete or rock drilling conditions. Quality control ensures that each diamond core bit meets operational standards and reduces the likelihood of premature failure in the field.

5. Customization and Application Flexibility

Many diamond core bit manufacturers offer customized solutions to meet specific project requirements. Variations in segment height, bond hardness, diamond concentration, and core diameter allow the bit to adapt to different materials and drilling speeds. This flexibility ensures that users can select bits suitable for soft concrete, reinforced structures, or abrasive natural stones. Customization helps increase efficiency and reduces tool wear during demanding tasks.

6. Maintenance and User Guidance

Diamond core bit manufacturers often provide guidance on usage and maintenance. Proper cooling, feed pressure, and rotation speed are critical to prevent overheating and premature wear. Maintaining these practices ensures that the bit remains effective for longer periods and reduces the need for frequent replacements. Some manufacturers also provide replacement segments or repair services to extend the operational life of the core bit.

Diamond core bit manufacturers play an essential role in producing tools that meet the demands of construction, mining, and industrial drilling. By combining careful material selection, precise segment fabrication, balancing, quality control, and customization, these manufacturers ensure durability, precision, and adaptability across different drilling scenarios. Proper user guidance and maintenance further enhance performance and reliability, making diamond core bits indispensable tools for a wide range of applications.