What Applications Suit a Vacuum Brazed Diamond Hole Saw?

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability and precision. A vacuum brazed diamond hole saw offers a solution that combines diamond abrasives with strong metal bonding. This specialized tool ensures faster cutting and longer service life compared to conventional hole saws. By examining its design, applications, and manufacturing process, we can better understand the advantages of using a vacuum brazed diamond hole saw in various industrial and construction projects.

1. Structure and Design

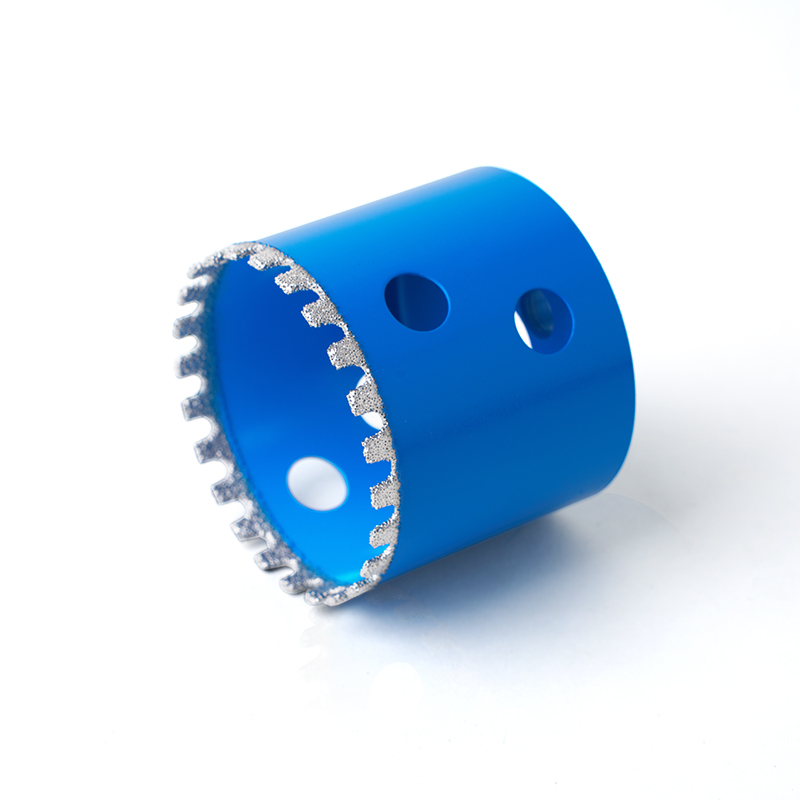

The design of a vacuum brazed diamond hole saw contributes directly to its effectiveness:

- Diamond Abrasive Layer: High-quality diamond particles are brazed onto the metal body using a vacuum process, ensuring strong adhesion.

- Metal Core: The base provides rigidity and stability during cutting operations.

- Open Slots or Flutes: These help remove debris and reduce heat buildup, extending the tool's lifespan.

The combination of diamond and metal ensures the saw maintains sharpness over extended use, even under demanding conditions.

2. Manufacturing Process

The production of a vacuum brazed diamond hole saw involves precise steps in a controlled environment:

- Diamond Selection: Manufacturers choose high-grade synthetic diamonds with consistent size and hardness.

- Brazing Process: Using vacuum brazing, the diamond particles are fused to the metal body at high temperatures, avoiding oxidation and ensuring strong adhesion.

- Finishing: The saw is ground and polished to achieve accurate diameter and smooth cutting edges.

- Quality Testing: Each hole saw undergoes cutting tests on representative materials to ensure performance and durability.

These steps ensure that the vacuum brazed diamond hole saw is capable of consistent and reliable performance.

3. Applications and Advantages

Vacuum brazed diamond hole saws are suitable for various scenarios:

- Construction: Ideal for drilling holes in tiles, bricks, concrete, and natural stone.

- Industrial Projects: Used in machinery installation or material sampling where precision holes are required.

- DIY and Home Renovation: Helps professionals and enthusiasts achieve clean, accurate cuts without damaging surrounding material.

Advantages include reduced cutting time, less tool wear, and cleaner hole edges compared to traditional hole saws.

4. Maintenance and Safety

Proper use and care extend the lifespan of a vacuum brazed diamond hole saw:

- Cooling: Using water or lubricant during cutting prevents overheating and prolongs diamond life.

- Storage: Keeping the saw in a protective case reduces the risk of damaging the diamond edge.

- Handling: Avoiding excessive lateral force maintains cutting precision and prevents early wear.

Routine inspection for wear or loose diamond particles ensures ongoing safety and performance.

5. Trends and Innovations

Manufacturers are continuously improving vacuum brazed diamond hole saws:

- Customized Sizes: Offering a variety of diameters and depths to suit specific projects.

- Advanced Brazing Techniques: Improved adhesion methods reduce diamond loss and increase lifespan.

- Eco-Friendly Production: Optimizing materials and reducing waste during manufacturing.

These innovations reflect how the tool adapts to both professional needs and environmental considerations.

A vacuum brazed diamond hole saw combines precision, durability, and efficiency, making it a valuable tool for construction, industrial, and DIY applications. Its careful design, specialized manufacturing process, and practical advantages ensure reliable performance on hard materials. By understanding its structure, applications, and maintenance requirements, users can maximize the tool's lifespan and achieve cleaner, faster, and more precise cuts across a range of projects.