Cooling Wax for Diamond Drill Bits

About

-

Target

To create an honest enterprise for the responsibility To build a harmonious society.

-

Vision

Let every employee work happily To be a sustainable business excellence With the integrity of the enterprise image deeply.

-

Core Values

Run the business with integrity Give back to society with a loving heart.

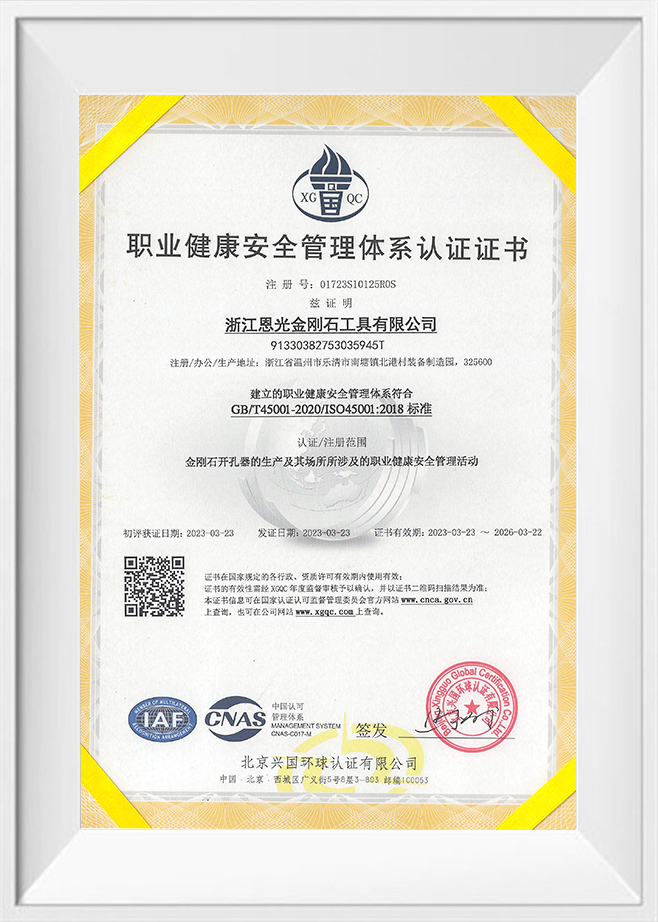

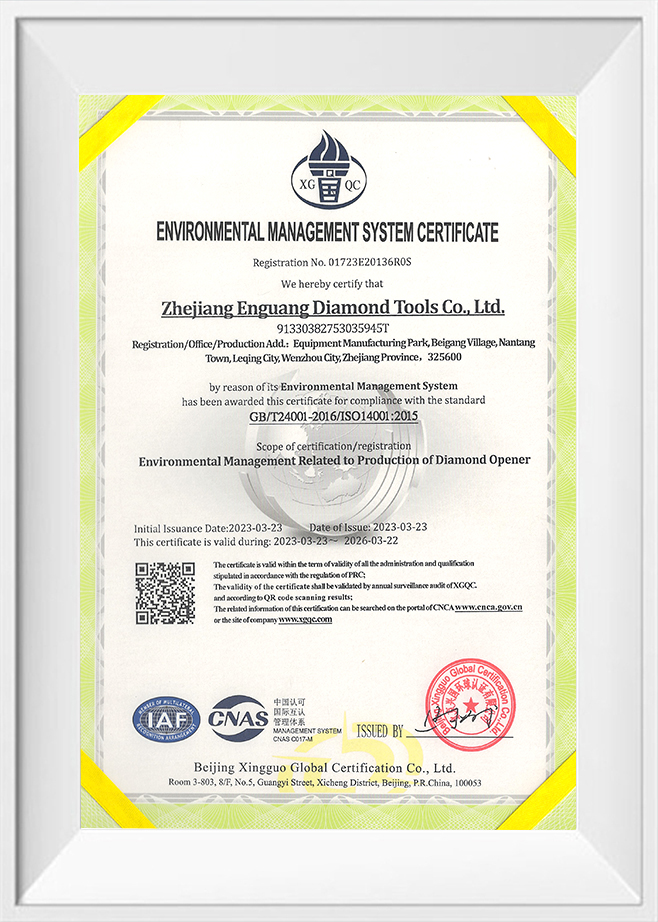

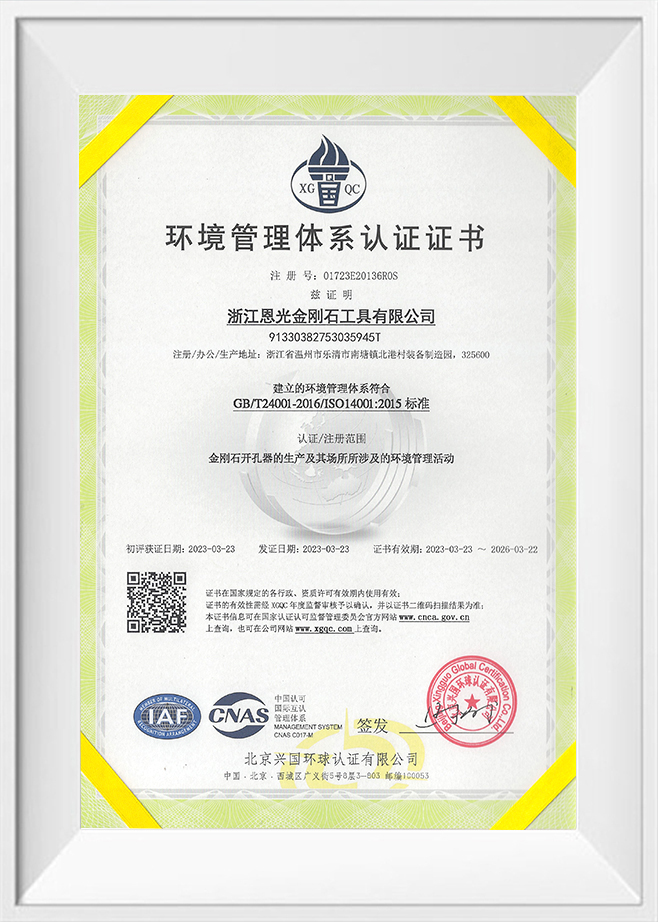

Zhejiang Enguang Diamond Tools Co., Ltd. was formally established in 2003, specializing in the production of diamond hole opener series products, which are suitable for opening holes in glass, ceramics, marble and other materials.

As a China high quality Cooling Wax for Diamond Drill Bits supplier and custom Cooling Wax for Diamond Drill Bits company, Enguang has a large number of CNC machine tools and green environmental protection electroplating workshops, which can provide customers with efficient and convenient ODM and OEM services to ensure long-term and stable production for customers!

-

Diamond core bits are essential tools for drilling concrete, stone, asphalt, and other hard material...

View More > 2026.02.24

2026.02.24

-

Drilling through hard materials such as ceramic tiles, granite, glass, or engineered stone requires ...

View More > 2026.02.20

2026.02.20

-

Tile installation, whether in residential or commercial projects, often requires precise cuts for pi...

View More > 2026.02.13

2026.02.13

-

In many construction and industrial applications, cutting through hard materials requires specialize...

View More > 2026.02.06

2026.02.06

-

Whether you are managing a construction project, running a manufacturing plant, or performing renov...

View More > 2026.01.27

2026.01.27

-

Whether you are a DIY enthusiast or a professional contractor, selecting the right cutting tool can...

View More > 2026.01.23

2026.01.23

-

A Polished Tile Hole Saw is designed specifically for cutting holes in polished tiles without causi...

View More > 2026.01.16

2026.01.16

-

A Vacuum Brazed Diamond Hole Saw is a specialized tool designed to cut through hard materials such ...

View More > 2026.01.09

2026.01.09

-

Drilling hard materials like concrete, stone, and ceramics requires tools designed for durability a...

View More > 2026.01.02

2026.01.02

-

Diamond core bits are essential tools in construction, mining, and geological exploration, allowing...

View More > 2025.12.25

2025.12.25

-

Drilling through hard materials such as ceramics, glass, or stone can be challenging with conventio...

View More > 2025.12.19

2025.12.19

-

Working with polished tiles can be challenging due to their smooth surfaces and risk of cracking du...

View More > 2025.12.12

2025.12.12

More Details About Cooling Wax for Diamond Drill Bits

Diamond drill bit cooling wax is an auxiliary material specially used for cooling and lubricating diamond drill bits. It plays a vital role in the use of diamond drill bits and can significantly improve the service life and working efficiency of the drill bits.

Diamond drill bit cooling wax is mainly composed of efficient cooling ingredients and lubricants, which usually include paraffin wax, synthetic wax, special additives, etc. Its unique formula design enables it to maintain stable performance under high temperature and high pressure conditions.

1. Paraffin wax: Paraffin wax is a common natural wax with good lubrication and protective properties. In cooling wax, paraffin wax can effectively reduce friction and reduce wear between the drill bit and the processed material.

2. Synthetic wax: Synthetic wax has a higher melting point and better stability and can work at higher temperatures. The addition of synthetic wax allows the cooling wax to maintain its effectiveness during long-term and high-intensity use.

3. Special additives: In order to enhance the cooling and lubrication effects, some special chemical additives are also added to the cooling wax. These additives can further improve the cooling effect, prevent the drill bit from overheating, and provide additional protection under conditions.

Diamond drill bit cooling wax achieves its cooling and lubricating effects in a variety of ways:

1. Physical cooling: During the rotation of the drill bit, the cooling wax absorbs and conducts heat to quickly take away the heat generated by the drill bit, preventing the drill bit from overheating and causing damage.

2. Lubrication: The cooling wax forms a lubricating film between the drill bit and the processed material to reduce friction and wear. This not only protects the diamond particles of the drill bit, but also improves the smoothness and accuracy of the drilling.

3. Protective effect: The cooling wax can form a protective film on the surface of the drill bit to prevent moisture, dust and chemicals in the external environment from eroding and damaging the drill bit, thereby extending the service life of the drill bit.

The use of diamond drill bit cooling wax is very simple, but in order to achieve the effect, you need to follow the following steps:

1. Preparation: Before using the cooling wax, make sure that the surface of the drill bit and the processed material is clean and free of impurities and oil.

2. Apply cooling wax: Apply an appropriate amount of cooling wax evenly on the drill bit, especially the diamond particle part. It can be applied manually or using a special waxing tool.

3. Start drilling: Start the drilling equipment and follow the normal drilling operation. The cooling wax will gradually melt and play a role during the drilling process.

4. Replenish cooling wax: During long-term or high-intensity drilling, the cooling wax may be consumed. At this time, it is necessary to replenish it in time to ensure that the drill bit is always in a good cooling and lubricated state.

5. Clean up after the end: After the drilling is completed, you can wipe the residual cooling wax on the surface of the drill bit with a clean cloth for the next use.

The efficient cooling performance of the cooling wax can quickly absorb the heat generated by the drill bit and prevent overheating, thereby improving work efficiency and ensuring safety. Secondly, its outstanding lubrication reduces the friction between the drill bit and the material, protects the diamond particles, prolongs the life of the drill bit, and improves the smoothness and accuracy of the drilling.

In addition, the protective film formed by the cooling wax on the surface of the drill bit effectively resists external erosion and maintains the good condition of the drill bit. Using cooling wax is simple to operate, does not require complex equipment, and is suitable for various drilling scenarios. It is economical and practical, reasonably priced, but can significantly improve work efficiency and extend the life of the drill bit, and is extremely cost-effective.

Diamond drill bit cooling wax is an essential auxiliary material, which plays an important role in various drilling operations. Its outstanding cooling, lubricating and protective properties not only improve the efficiency and quality of drilling, but also significantly extend the service life of the drill bit.